vacuum feeder machine

Vacuum feeder machine, also known as vacuum conveyor, is a kind of dust-free closed pipeline conveying equipment to transfer particles and powder materials with the help of vacuum suction. The pressure difference between vacuum and environmental space is used to form gas flow in the pipeline, driving the movement of powder materials, so as to complete the conveying of powder.

- Applicable Industries: Food industry, Chemical industry

- Type: pneumatic and electrical drive

- Feeding materials: Powder Material+particle/granule

- Machine material:carbon steel/ Material contact in SS/ Full SS

Product Introduction

Vacuum feeder machine, also known as vacuum conveyor, is a dust-free closed pipeline conveying equipment that uses vacuum suction to convey particles and powdered materials. It uses the pressure difference between vacuum and ambient space to form gas flow in the pipeline, drive the movement of powdered materials, and thus complete the conveying of powders. my country has introduced advanced foreign vacuum technology, continuously improved and improved it, and it is now widely used in chemical, pharmaceutical, food, metallurgical, building materials, agricultural and sideline industries and other light and heavy industries.

Vacuum feeder machine is a closed pipeline conveying method. This conveying method can eliminate dust environmental pollution, improve the working environment, reduce environmental and personnel pollution to materials, and improve cleanliness; because it is pipeline conveying, it occupies a small space, can complete the powder conveying in a small space, and make the workroom space beautiful and generous; especially not limited by long and short distances. At the same time, the vacuum feeder can reduce the intensity of manual labor and improve work efficiency; it is the first choice for most powder material conveying methods.

Pneumatic Vacuum Conveyor

| Air supply(L/Min) | Capacity(kg/h) | Air pressure(MPa) | Dimension(MM) |

| 180 | 350 | 0.4-0.6 | φ140*600 |

| 360 | 700 | 0.4-0.6 | φ213*800 |

| 720 | 1500 | 0.4-0.6 | φ290*1050 |

| 1440 | 3000 | 0.4-0.6 | φ420*1350 |

| 2880 | 6000 | 0.4-0.6 | φ420*1350 |

| 4320 | 9000 | 0.4-0.6 | φ420*1350 |

Electric vacuum feeder Machine

| Power(kw) | Hopper diameter(mm) | Capacity(kg/h) |

| 1.5 | Φ220 | 200 |

| 2.2 | Φ220 | 500 |

| 3 | Φ290 | 1000 |

| 5.5 | Φ420 | 2000 |

| 5.5 | Φ420 | 3000 |

| 7.5 | Φ420 | 4000 |

| 7.5 | Φ600 | 5000 |

| 7.5 | Φ600 | 6000 |

| 11 | Φ600 | 8000 |

Structural components

- Fans: Roots fans, vortex fans, water circulation vacuum pumps, centrifugal fans, suspension fans, etc.

- Feeder: pneumatic butterfly valves, pulse control, cartridge filter cartridges, silo wall vibrators, discharge butterfly valves

- Materials: stainless steel, carbon steel, lined with ceramics, sprayed with Teflon coating, sprayed with tungsten carbide coating

Details

Working Principle

The working principle of the vacuum feeder machine is as follows: it generates a vacuum through a vacuum pump (based on the Venturi principle), and then uses the negative pressure generated by this vacuum to suck the material from the feed port. In the filter bin of the separation container, the air and the material are effectively separated. The material falls automatically due to gravity and is collected in the silo. In particular, the cyclone separator of the powder vacuum feeder is designed to prevent fine powder from entering the filter, thereby improving the efficiency of the filter.

When the silo is full of material, the vacuum pump is automatically turned off to achieve pressure balance in the conveying equipment. Subsequently, the discharge valve is opened, and the material flows out through the discharge port and falls directly into the storage container. During the discharge process, the filter element is automatically cleaned by the back-blowing airbag. When the material is discharged, the discharge chamber is automatically closed, thus starting the entire conveying process.

Product Show

Features

- High-efficiency dust-free conveying: Adopting airtight vacuum conveying, eliminating dust leakage and ensuring a clean production environment, especially suitable for food, pharmaceutical, chemical and other industries.

- Low energy consumption: energy-saving design combined with advanced vacuum technology greatly reduces energy consumption, and the running cost is lower than traditional pneumatic conveying.

- Flexible adaptation to a variety of materials: powder, granules, flakes and other dry materials can be easily transported to avoid layering, crushing or clogging problems.

- Automatic control: PLC intelligently adjusts conveying volume, pressure and other parameters, realizing unattended operation and improving production efficiency.

- Modularized structural design: Quick-disassembly filter and stainless steel material, easy to clean and maintain, in line with GMP, FDA and other stringent certification standards.

- Quiet and low wear and tear: optimized airflow path and wear-resistant materials, the equipment noise <65dB, the core components to extend the life of more than 30%.

Application

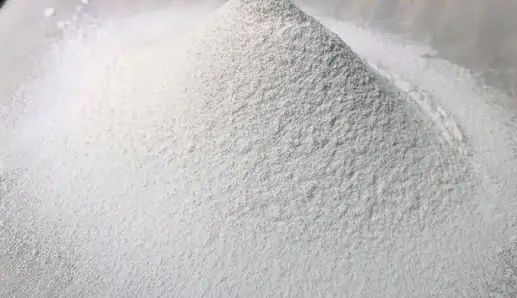

The vacuum feeder is mainly used to convey powder and granular materials, such as raw material powder, chemical powder, metal oxide powder; capsules, tablets, pills, small food particles, etc.; it is not suitable for conveying overly wet, sticky, and heavy materials.

Spices

Spices Yeast Powder

Yeast Powder Sugar

Sugar Wheat Flour

Wheat Flour Food Additives

Food Additives Metal Powder

Metal Powder Graphite Powder

Graphite Powder Cyclamate

Cyclamate Medicine Powder

Medicine Powder Vitamin E powder

Vitamin E powder

- Chemical Industry: Resin, industrial chemicals, pigments, dyes, coatings, plastic particles.

- Food Industry: Sugar, flour, starch, milk powder, spices, additives, food-grade powders.

- Pharmaceutical Industry: APIs (active pharmaceutical ingredients), excipients, granules, powdered medicines, Chinese herbal extracts.

- Metallurgy & Mining: Metal powders (aluminum, copper, etc.), mineral powders, welding materials, refractory materials.

- Abrasives & Ceramics: Alumina, silicon carbide, quartz sand, kaolin, ceramic powders.

- New Energy & Electronics: Battery materials (lithium cobalt oxide, graphite), electronic-grade powders, magnetic materials.

Cases Show

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization