Tumbler Screening Machine

Tumbler Screening Machine is a kind of vibration screen to a large extent simulation of artificial screening motion, swing screen is the vibration screen simulation of artificial screening, suitable for screening all kinds of materials, including fine, ultra-fine powder materials, screening precision, rate, screen life and other indicators are 5-10 times the conventional round screen.

- Function: Fine Screening

- Deck(s): 1-5 layers

- Diameter: 1200-2600mm

- Application: Dry powder and small granule

- Machine material:carbon steel/ Material contact in SS/ Full SS

Product Introduction

The tumbler screening machine is modeled on a simple screening method binocular two-handed screening, which is currently effective in simulating the effective principle of manual screening motion. Screening accuracy of more than 95%, high speed, screen life is more than 3 times of conventional screening equipment, output is also 3-5 times of ordinary screening equipment. Meet all fine and ultrafine range of powder and particulate materials, especially suitable for difficult to handle and high yield materials.

The motion mode of the Tumbler Screening Machine is similar to that of the manual screening. The eccentricity can be adjusted from 25 to 40mm. The low-speed V-belt drive can be adjusted from 120 to 360rpm. The residence time of the screening material can be adjusted through its radial and cutting Angle towards the driving axis direction; The movement of the product is a horizontal and throwing three-dimensional tumbling motion, it makes the material from the center to the outer edge of the whole screen surface evenly dispersed, so as to spiral motion to axial propagation, fine particles thus complete the whole screening process; The movement of the material particles increases with the horizontal and vertical acceleration, and the material particles close to the size of the sieve are separated successfully. Larger particles are transported to the outlet and handled by an adjustable guide.

Working Principle

The tumbler screen replicates manual sieving by combining circular and parabolic motions to create a three-dimensional elliptical movement. This design enhances material screening efficiency to over 99%, making it ideal for precision classification, grading, and dedusting of dry powders and granular materials. It excels in high-capacity processing and multi-layer separation of fine, fragile, or lightweight particles that are typically challenging to screen. With its five-deck configuration, the system can classify materials into up to six distinct size fractions.

Features

- Adopt frequency conversion speed control technology, adjustable screening efficiency, adapt to different material characteristics.

- Fully closed structure design, effectively prevent dust spillage, in line with environmental requirements.

- Multi-layer screen configuration (1-5 layers), to realize multi-level accurate classification.

- Low noise operation, suitable for clean workshop environment.

- Quick-disassembly sieve frame design, complete sieve replacement within 3 minutes, improve maintenance efficiency.

- Cleaning methods: bouncing ball cleaning, ultrasonic cleaning and rotary brush cleaning.

Application

- Chemical industry: resin pigment, calcium carbonate, decorative coatings, medicine, etc.

- Abrasive material and ceramic industry: building sand, alumina, silica sand, abrasive, refractory material, slurry, etc.

- Mechanical industry: casting sand, charcoal, grafito, powder metallurgy, metal powder, etc.

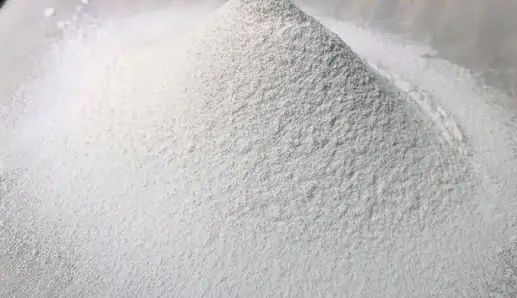

- Food industry: sugar, salt, alkali, flour powder, farina, gourmet powder, starch, milk powder, yeast powder,etc.

Metal Powder

Metal Powder Sugar

Sugar Wheat Flour

Wheat Flour Yeast Powder

Yeast Powder Food Additives

Food Additives Graphite Powder

Graphite Powder

Specifications of Tumbler Screening Machine

| Model | Mesh zrea(㎡) | Granularity(mm) | Amplitude(mm) | Power(kw) |

|---|---|---|---|---|

| ARSYS-600 | 0.28 | ≤100 | 20-70 | 0.75 |

| ARSYS-1000 | 0.66 | ≤100 | 20-70 | 1.5 |

| ARSYS-1200 | 0.98 | ≤100 | 20-70 | 2.2 |

| ARSYS-1500 | 1.67 | ≤100 | 20-70 | 3.0 |

| ARSYS-1800 | 2.37 | ≤100 | 20-70 | 4.0 |

| ARSYS-2000 | 2.89 | ≤100 | 20-70 | 4.0 |

| ARSYS-2600 | 5.3 | ≤100 | 20-70 | 5.5 |

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization