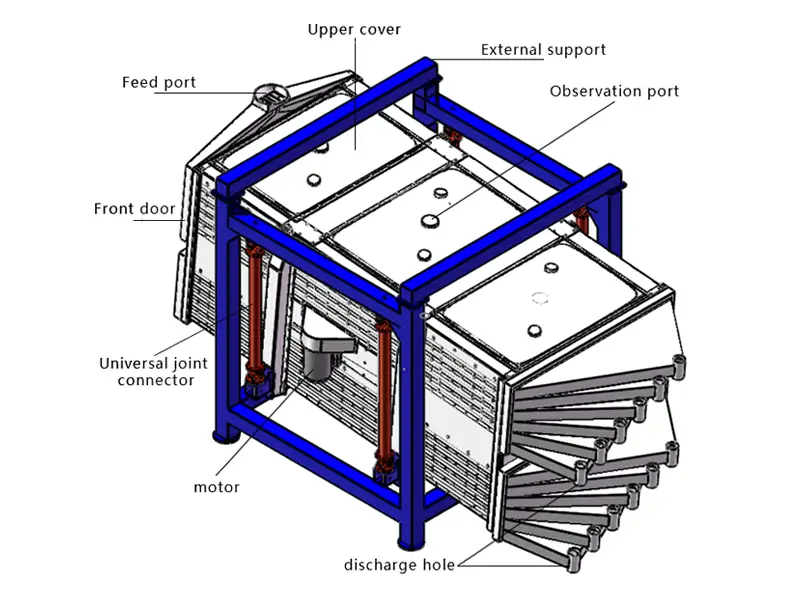

Square Gyratory Sifter

Square Gyratory Sifter is driven by the motor, the pulley variable speed, so that the material in the sieve surface presents an oval linear movement, and then achieve the classification effect of the sieving machine. Handling capacity depends on the width of the screen surface, screening accuracy depends on the length of the sieve machine, commonly used models have 1536 and 2040 type, according to the demand for single-deck and compound, rotating speed between 240-290 rpm, dealing with dry powder and granular materials!

- Material: Carbon Steel

- Mesh Size: 2-300 mesh

- Layers: 1-10 layers

- Capacity: 500kg – 13 Tons/hour

Structure composition

Driving part: motor, pulley, shaft, eccentric weight block

Box: inlet, fabricator, outlet, perforated plate, bouncing ball, screen, bottom plate, side plate, observation port, dust removal port

Sealing: sponge skin sealing, steel wire hose connection

Mesh frame: hooked edges clamped to the two sides of the screen, through the fixed in the side panel of the wire tightening

Details Show

Working principle

Motor drives the whole box, the material in the sieve surface The material is reciprocating back and forth on the screen surface, the material smaller than the aperture of the screen mesh enters into the next layer, and the material larger than the screen mesh is intercepted in the upper layer, so as to achieve the screening effect.

Specifications

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS1536 | 1.5*3.5 m | 4.5-9 m2 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 mm |

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

Products Show

Features

- Fully enclosed design, the top of the dust port can be connected to the central dust collection

- large screening capacity

- high screening accuracy

- not blocking the screen, continuous operation

- easy maintenance and dismantling, screen mesh pull-out design, quick change of mesh

Application

Used in building materials, chemical industry, medicine, food, new energy and other industries, applicable to particles, powder and a variety of materials.

Wheat Flour

Wheat Flour Sugar

Sugar Light calcium powder

Light calcium powder

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization