Inline Sifter Machine

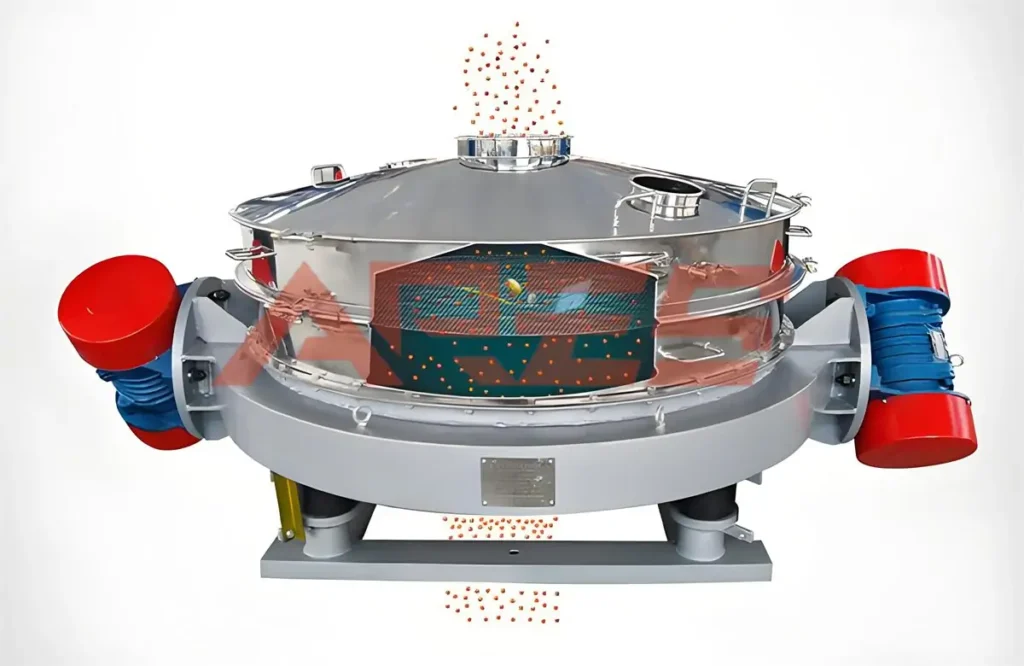

The Inline Sifter Machine is a relatively simple and highly efficient screening device that uses a horizontal dual-vibration motor to generate vibrational force. The feed inlet and discharge outlet are aligned on the same straight line, facilitating rapid material discharge, reducing screening time, and achieving high output. It is constructed with all-stainless-steel materials and features a fully enclosed structural design, ensuring environmental friendliness and high efficiency.

- Mesh size: 2-500 mesh

- Capacity: 100-3300kg/h

- Screen frame: 1-5 layers (3 layers is best)

- Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

- Motor power: 0.25Kw to 2.2Kw or customized

- Power supply: 220/240/380/415/450V can be used. 50 or 60HZ.

- Application: Suitable for dry or wet applications such as silica, ceramics, powder coatings, tapioca starch, coffee beans, copper powder, silver powder, etc.

Structures

- Screen Box: The main frame of the equipment, supporting the screen mesh for stability and ensuring the overall structural strength of the equipment.

- Screen Mesh: The primary component for screening, featuring a multi-layer design with sufficient strength and wear resistance. It is installed on the upper and lower surfaces of the screen box, with different mesh sizes to screen various materials.

- Vibration System: Comprising components such as motors, eccentric weights, and couplings, it can be configured with single or dual motors. Installed on both sides of the screen machine, it adjusts vibration parameters and frequency to meet different screening requirements.

- Discharge Port: Located at the bottom of the machine, it vertically discharges the screened material.

- Feed Port: Positioned at the top of the machine, it receives the material. It offers both manual and automatic feeding options.

Working principle

The Inline Sifter Machine generates vibrational force through horizontal motors on both sides, which is transmitted to the screen mesh. The material undergoes repeated elliptical motion on the screen surface, rapidly dispersing the material. Particles smaller than the screen mesh openings are quickly discharged through the lower discharge port, while larger particles are discharged through the upper discharge port, thereby achieving the screening objective. By adjusting the phase angle and weight of the upper and lower eccentric blocks, the magnitude of the vibrational force and the material’s motion trajectory can be modified.

Features

- High screening capacity: the feed and discharge ports are aligned vertically, enabling rapid material passage through the screen and swift discharge.

- High screening accuracy: can be used in single or multiple layers, allowing for multi-stage screening in a single pass to meet various screening accuracy requirements.

- Compact design; space-saving: the motor is mounted on the exterior of the equipment, reducing overall height and maximizing space utilization.

- Environmentally friendly and energy-efficient: no dust pollution, fully enclosed structure prevents dust dispersion, low noise, low energy consumption, and high efficiency.

Application

- Food Industry: Used for de-contamination and screening of flour, starch, milk powder, cocoa, coffee, seasonings, etc.

- Chemical Industry: Suitable for screening of particles or powders such as resins, plastics, rubber additives, dyes, fillers, lime, cement, coal powder, etc.

- Pharmaceutical Industry: Can be used for screening and de-contamination of raw materials for traditional Chinese medicine, Western medicine, and traditional Chinese medicine formulations.

- Metal Industry: Can be used for the screening of metal powders and alloys such as aluminum, lead, zinc, copper, iron, nickel, and magnetic materials.

- Other Industries: In the abrasive industry, used for the screening of glass beads, alumina, corundum, etc.; in the ceramics/paper industry, used for clay screening and fiber selection; can also be used for solid-liquid separation in wastewater, etc.

Wheat Flour

Wheat Flour Cereal Grains

Cereal Grains Spices

Spices Oreo powder

Oreo powder Stevioside Powder

Stevioside Powder Medicine Powder

Medicine Powder Lees

Lees Medicine

Medicine Plastic Additives

Plastic Additives Plastic Particles

Plastic Particles

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization