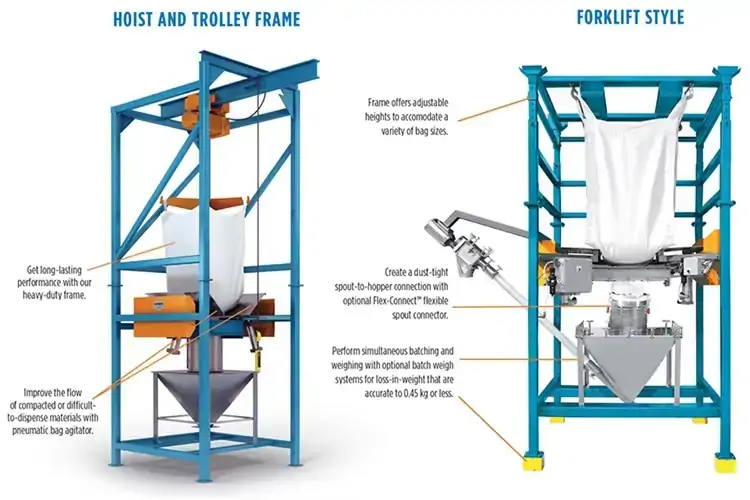

Bulk Bag Discharge Station

Bulk Bag Discharge Station is a kind of material used to deal with ton bag packaging, it is through the lifting device, the material will be lifted to a suitable height, complete the automatic unpacking and discharging or manual unbagging. It realizes the process of feeding, dust removal, filtration and unloading, and is applied in the fields of medicine, food, chemical industry, building materials, new energy and so on.

- Material: Food Grade Stainless Steel

- Unpacking specifications:≤100010001600

- Working power supply:AC380V±5%50Hz

- Air supply pressure:≥0.6MPa

- Ability to unpack bags:5-10 bags/h

Structure and Composition

- Ton bag lifting device: lifting the ton bag to the feeding position through the motor

- Bag opening device: open the tonnage bag through mechanical unbagging or manual unbagging.

- Dedusting device: collect and deal with the dust generated in the feeding process through cyclone dust collector.

- Flow-assisting device: Fluidizing disk and vibrator, assisting the material to fall down and reducing the material residue.

- Electrical control system: according to the need, can be point or linkage control, handle and wireless control.

Working Principle

First of all, open the dust removal system, through the electric hoist and other lifting devices, the tonnage bag will be hoisted to the feeding station above, manually or automatically open the bottom of the tonnage bag, the material from the tonnage bag falls into the hopper below, the vibration of flow-assisting devices can assist the material to fall, the unloading of the dust generated in the process of the dust removal device will be sucked in by the dust removal device, filtering devices to retain the dust, the clean air is discharged, and the feeding process is completed.

Product Show

Specifications

| Unpacking specifications | Working power supply | Air supply pressure | Ability to unpack bags |

|---|---|---|---|

| ≤1000*1000*1600 | AC380V±5%50Hz | ≥0.6MPa | 5-10 bags/h |

Application

The Bulk Bag Discharge Station is widely used in chemical, food, pharmaceutical, building materials, plastics, metallurgy, new energy and other industries, suitable for automatic unloading of powder, granule, flake, fiber and other dry bulk materials, such as fertilizer, starch, milk powder, carbon powder, plastic particles, quartz sand, lithium-ion materials, and so on. Its sealing and dustproof design is especially suitable for high cleanliness requirements (such as GMP workshop) or environmentally friendly working conditions, can be seamlessly connected to the conveying, mixing, packaging and other equipment, to achieve high efficiency and low loss of intelligent production.

Spices

Spices Yeast Powder

Yeast Powder Sugar

Sugar Wheat Flour

Wheat Flour Food Additives

Food Additives Vitamin E powder

Vitamin E powder Metal Powder

Metal Powder Graphite Powder

Graphite Powder Cyclamate

Cyclamate Medicine Powder

Medicine Powder

Features

- 1. Simplified Structure & Easy Operation: Compact and robust design, user-friendly controls for quick setup and minimal training. Reduces manual handling, improving efficiency and workplace safety.

- 2. Wide Compatibility & High Capacity: Accommodates various FIBC/bulk bag sizes (500kg–2,000kg) for versatile material handling. Large discharge volume replaces labor-intensive processes, boosting productivity.

- 3. Sealed Design & Dust-Free Discharge: Fully enclosed feeding zone with integrated dust extraction (negative pressure system). Ensures clean operation, complies with EH&S and environmental regulations.

- 4. Vibration-Assisted Emptying & Minimal Residue Optional vibrators promote complete discharge, reducing material waste (<1% residue). Ideal for high-precision industries (e.g., food, pharmaceuticals, chemicals).

- 5. Heavy-Duty & Safe Construction: Reinforced frame and load-bearing components ensure stability for heavy bags (up to 2T). Safety features include anti-slip platforms and emergency stop controls.

- 6. Automation-Ready Integration: Seamlessly connects with conveyors, mixers, or silos for streamlined production lines. Supports powders, granules, and other bulk solids in diverse industries.

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization