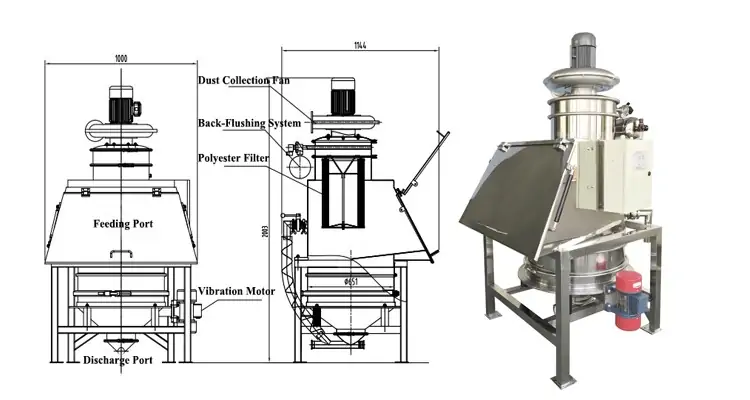

bag dump sieve station

Bag dump sieve station is a kind of independent equipment, which is also an important link in the production process, and can effectively solve the dust problem in the process of powder and granular materials feeding. It is widely used in food, medicine, chemical industry, new energy and other industries, suitable for a variety of production scenarios: after feeding the material can be directly into the downstream receiving equipment, or through the screw conveyor or vacuum feeder for secondary transfer, high flexibility.

- Machine material: Stainless steel

- Feeding materials: Powder Material+particle/granule

- Advantages: Efficient transportation, clean and environmentally friendly

- Applicable Industries: Food, chemical industry, medical treatment, ore and building materials

Product Introduction

Bag dump sieve station adopts the design of fully enclosed structure, in line with environmental protection requirements; through the centrifugal fan negative pressure adsorption technology, to ensure that the material does not overflow, to achieve fast and efficient feeding; feeding height optimized according to ergonomics, significantly reducing the labor intensity of workers, while improving the operating environment, to protect health and safety; built-in vibrating screen with filtration function, can intercept large particles and foreign objects, to improve the quality of the product; equipped with pulse blowback self-cleaning system, to support continuous operation. This machine is widely used in food, pharmaceutical, food processing and other industries.

Specifications

| Model | ATLZ-400 | ATLZ-600 | ATLZ-800 | ATLZ-1000 | ATLZ-1200 | ATLZ-1500 |

| Power (Dual-Motor) | 0.13kw*2 | 0.18kw*2 | 0.18kw*2 | 0.25kw*2 | 0.55kw*2 | 0.75kw*2 |

| Screen Diameter | 350mm | 550mm | 750mm | 920mm | 1120mm | 1420mm |

Parts

Bag dump sieve station is mainly composed of the following parts:

Feeding silo

Compact design of the feeding silo, occupies a small area, slow platform, hydraulic opening door, half-arc silo body, one-piece control box, full sealing design.

Dust removal filter blowback

by the centrifugal fan generates negative pressure, built-in filter element, the filter element intercepts the material to achieve solid gas separation, the material stays in the bin, the clean gas is discharged. The material attached to the filter element is self-cleaning through pulse blowback, and it runs continuously week after week.

Downstream equipment connection

It is directly installed above the receiving equipment, and the material is discharged by its own weight; it is transported through the screw conveyor for the second time; and it is lifted by the vacuum loader.

Control system

Adjustable control, one-button start.

Vibrating screen

Provide power for the circular vibrating screen to vibrate the screen mesh to help the material screening and falling, and also can be installed on the storage bin or falling bin to prevent the material from bridging and bonding.

Details Show

Working Principle of Bag dump sieve station

The material enters into the equipment through the feeding port to form a closed space, the dust removal fan outside the equipment starts, forming a negative pressure in the feeding area and the discharge channel, so that the dust is adsorbed inside the equipment and can not be spread to the surrounding environment, the negative pressure will be raised by the dust into the dust removal system, through the cartridge, filter bags and other filtration, the dust is intercepted, and clean air is discharged by the fan through the process, not only complete the material feeding and transfer, but also to realize the material bridging and bonding. Through this process, not only the material feeding and transfer, but also realize the efficient control and recovery of dust.

Products Show

Advantages

Health and environmental protection: Adopts a fully sealed structure with a negative pressure suction system, which efficiently inhibits the spread of dust, creates a clean working environment, reduces the risk of workers coming into contact with harmful dust, and protects occupational health and safety.

Effortless and efficient operation: The height of the feeding port is ergonomically designed to support manual or mechanical operation; some models are equipped with an automatic lifting device, which significantly reduces labor intensity and improves work convenience.

Optimization of production efficiency: Automated feeding and precise control system ensures fast and accurate material feeding; closed design prevents material scattering and reduces cleaning time; built-in filtration and emission purification module ensures continuous and stable operation of the equipment and reduces downtime.

Enhanced safety performance: The dust emission control effectively eliminates explosion and fire hazards, and reduces the incidence of occupational diseases, creating a safer production environment.

Easy and Flexible Maintenance: The modular internal structure allows for quick disassembly and cleaning, and the filter element can be replaced at the touch of a button, making it especially suitable for harsh conditions where frequent material changeovers are required.

Application

Spice Powder

Spice Powder Wheat Flour

Wheat Flour Sugar

Sugar Milk Powder

Milk Powder Yeast Powder

Yeast Powder Food Additives

Food Additives Light calcium powder

Light calcium powder API

API

The Bag Dump Sieve Station is mainly used in powder/granular material scenarios that require dustproofing, sieving and automated feeding.

- Food industry: powder feeding such as milk powder, flour, additives, etc.

- Pharmaceutical industry: sealed transfer of APIs, excipients, granules

- Chemical industry: dust-proofing of pigments, plastic granules, catalysts, etc.

- New energy industry: precision sieving of Li-ion battery materials, photovoltaic powders, etc.

- Pesticides/fertilizers: explosion-proof design to avoid the danger of dust

- Feed industry: clean feeding of granular raw materials

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization