Ultrasonic Vibrating Screen

Ultrasonic Vibrating Screen is a traditional vibrating screen that adds ultrasonic waves. Through a sound converter, electrical energy is converted into sound energy, causing the mesh frame to vibrate at a high frequency. The material is quickly screened and is suitable for materials that are prone to sticking to the mesh. It is mainly used to solve problems such as mesh clogging, adsorption, static electricity, and low screening efficiency that are prone to occur in the screening of fine powders.

- Mesh Size: 10-635 Capacity:1-20t/hLayer:1~5 layers

- Material: Stainless steel 304,316L,or Carbon Steel

- Voltage: 3 phase, 220V/ 380V/ 415V, 50HZ/60HZ(Customized is available)

- Application:Strong adsorption, adhesion, sticky, high static, high density, ultrafine powder, etc.

- Customizable: external type/built-in type, gate type, gas protection type

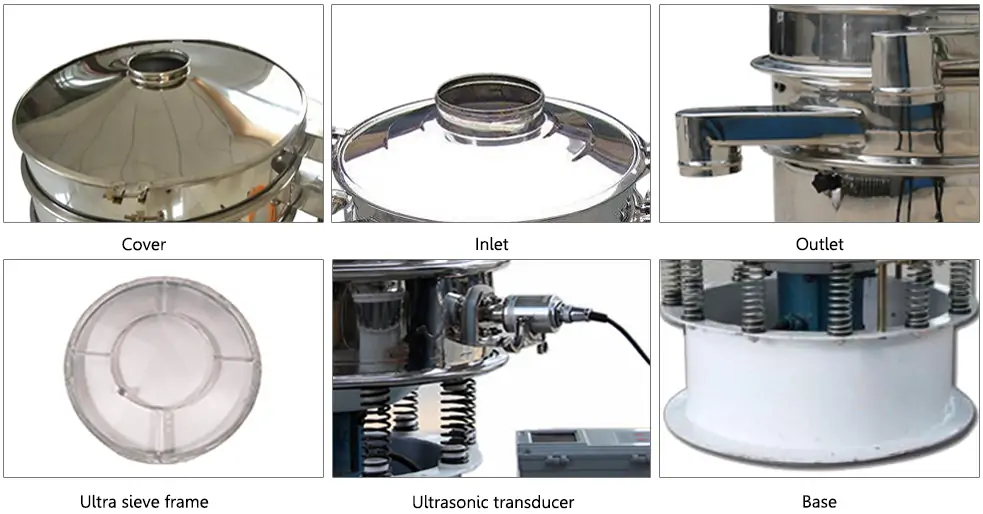

Structural Composition

Composition of the Ultrasonic Vibrating Screen

- Base: Typically circular in shape, it serves to secure the motor and support the screen frame and mesh.

- Screen Mesh: Used for material screening, different mesh sizes are applied based on material particle size. Made of stainless steel, alternative materials may be selected depending on the specific material.

- Motor Counterweight: Provides the primary vibrational power. Combined with the counterweight, it induces three-dimensional movement of the material on the screen, enabling efficient screening.

- Vibration Damping Device: Installed beneath the base, it reduces friction between the equipment and the ground, protects the machine, and lowers noise levels.

- Ultrasonic Device: High-frequency vibrational energy is transmitted through a guide rod, causing the material to jump on the screen, enhancing cleaning efficiency, and improving screening efficiency and accuracy.

Working principle

The working principle is as follows: the electrical box controls the transducer, converting electrical energy into high-frequency vibrational energy, which is transmitted through the control rod to the ultrasonic mesh frame. The material can jump at a high frequency on the screen, quickly removing any adhering material from the mesh, thereby enhancing the cleaning effect, improving screening efficiency, and increasing accuracy.

Features and Advantages

The Ultrasonic Vibrating Screen has the following features:

- High screening capacity: Compared to ordinary vibrating screens, it offers higher screening capacity and greater screening precision.

- Reduced screen clogging: The ultrasonic vibration waves on the screen accelerate material flow through the screen, addressing issues such as material adhesion and screen clogging, thereby extending the screen’s service life.

- Durable equipment: Extended screen mesh lifespan, easy disassembly and assembly, and stainless steel construction meet hygiene and cleanliness requirements for the food and pharmaceutical industries.

- Wide material adaptability: Effectively addresses screening challenges for materials with strong adhesion, tendency to agglomerate, high static electricity, high precision, high density, or low specific gravity, such as graphite powder, silica micro powder, plastic pellets, soybean flour, resin, and rubber powder.

Applicable Materials

- Chemical Industry: Resin powder, pigments, dyes, carbon black, paint powder, catalysts, fluorescent powder, etc.

- Pharmaceutical Industry: Traditional Chinese medicine powder, Western medicine powder, pharmaceutical excipients, health supplement powder, antibiotic powder, etc.

- Food Industry: Flour, starch, milk powder, coffee powder, cocoa powder, sugar powder, spice powder, etc.

- Mining and new materials: graphite powder, diamond powder, metal powders (aluminum powder, copper powder, etc.), ceramic powder, glass powder, rare earth powders, etc.

- Others: battery materials (cathode materials, anode materials), cosmetic raw materials, coating additives, etc.

Related Articles

Get Free Quote

To request more information or a quote for one of our sieving machine, conveyor machine, pressing equipment, mixing equipment, or production line solutions, please fill out the form below, and we will get back to you as soon as possible.

- One-Stop Screening & Conveying Solutions

- Free Sample & Testing Machine

- Real-time Video Testing & Professional Analysis

- 48 Hours Rapid Solution Customization